Grease Traps, Hoods, and Precipitators: The Evolution of NYC’s Commercial Kitchen Ventilation

In a Midtown Manhattan diner, and a crew of commercial kitchen hood installers is hard at work above the empty griddle.

BROOKLYN, NY, UNITED STATES, June 18, 2025 /EINPresswire.com/ -- It’s 3 a.m. in a Midtown Manhattan diner, and a crew of commercial kitchen hood installers is hard at work above the empty griddle. Joey “Two-Tools” Ferraro, a veteran of the trade, wipes his brow and gestures at the massive stainless steel hood. “Back in da day, we didn’t have all dis fancy equipment,” he says in a thick New York accent, recalling decades of kitchen ventilation history. “Ya had a basic hood, a fan, and a whole lotta elbow grease. Now? We got precipitator kitchen systems, high-tech filters – it’s a whole new ballgame, but it’s still a tough hustle.” His words echo the journey of an industry that has quietly kept New York City’s restaurants safe and compliant for over a century.In the early 20th century, before modern kitchen hood installation service companies existed, restaurant ventilation was often primitive. Many eateries simply opened windows or relied on brick chimneys to vent smoke. The first breakthroughs came in the 1920s: in 1926 a New York inventor, Theodore R. N. Gerdes, applied for a patent on a “ventilating hood for ranges” – essentially the first modern range hood. Gerdes’s design used an electric fan to capture cooking fumes, an innovation that laid the groundwork for today’s powerful exhaust hoods. By the 1930s, pioneers like Henry Broan were manufacturing electric kitchen exhaust fans, and commercial kitchens in NYC’s burgeoning restaurant scene eagerly adopted these early hoods.

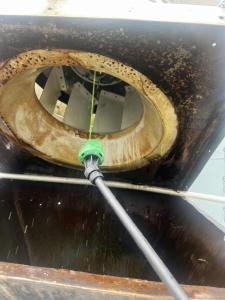

Throughout the mid-1900s, commercial kitchen hood installers became a specialized trade as restaurants expanded and fire hazards became apparent. Large supper clubs and hotel kitchens installed steel canopy hoods with fans to pull out heat and grease-laden smoke. However, these early systems were rudimentary by today’s standards. Grease filters were basic or non-existent, meaning a lot of oily vapor just blew into ducts – and often lingered there. “Ya see dis?” asks Vinny, a Filta Kleen crew chief, shining his flashlight on a blackened duct in a Little Italy pizzeria. “That grease buildup – that’s what we used to deal with all the time. It ain’t just dirt; it’s a ticking time bomb if you don’t take care of it.” He’s not exaggerating. Grease accumulation inside ducts and hoods would later be identified as a leading cause of restaurant fires.

By the 1970s, a series of high-profile kitchen fires and a growing understanding of fire prevention led to stricter regulations. New York City authorities, together with national standards like NFPA 96 (which addresses ventilation control and fire protection for commercial cooking), began mandating better designs and maintenance for kitchen exhaust systems. Automatic fire suppression systems (sprinklers or chemical agents inside hoods) were required to combat flare-ups, and hood exhaust repair and upkeep became a routine part of restaurant life. If an exhaust fan broke down, you fixed it fast – or risked fines and fire danger.

Over time, the city’s Fire Department (FDNY) enacted detailed rules to enforce compliance. One veteran installer recalls how the job evolved: “Years ago, you installed a hood and hoped for da best. Now the City wants proof everything’s by the book,” he says, referring to measures like FDNY’s requirement for cleaning companies to place official decals on cleaned exhausts as proof of service. Indeed, since 2018, NYC Fire Code Section 115-02 has required that only licensed and FDNY-certified contractors perform hood cleanings, tagging each job with a numbered sticker to keep restaurants honest. This push for accountability means kitchen hood installation service providers in NYC not only install equipment, but ensure it meets code and is regularly maintained.

Thick grease buildup inside a restaurant’s exhaust duct before cleaning – a serious fire hazard if left unaddressed. Regular professional cleanings (often required quarterly or semi-annually) are mandated to prevent dangerous conditions like this from sparking a blaze.

The heightened scrutiny was driven by sobering statistics. Fire experts note that flames in a busy kitchen can quickly spread via grease-laden ducts if not properly cleaned. Oven hoods themselves become fire hazards when coated with grease; if the nightly wipe-down gets skipped too often, an invisible disaster is brewing above the flattop grill. NYC’s solution has been aggressive: most commercial kitchens here are required to have their exhaust systems professionally cleaned at least once every three months to stay within code. Restaurateurs who might be tempted to put off the $500 professional cleaning bill are playing with fire – literally. “It’s just one of those tings – hood cleanin’ has to happen, period,” says Sal, an exhaust technician. “If a place can’t afford to do it, they sure can’t afford a kitchen fire either.” The National Fire Protection Association recommends even more frequent cleanings (monthly or quarterly) for high-volume operations, and the FDNY has not been shy about enforcing these timelines.

Ventilation wasn’t the only challenge. Down below, under sinks and streets, another battle was raging – this time against grease in the water. Every NYC restaurateur knows that grease trap cleaning is as fundamental as taking out the trash. In fact, the law requires all restaurants and food businesses to install grease interceptors to keep fat, oil, and grease (FOG) out of the city sewers. “New Yawk’s got old pipes,” says Carmen, a Filta Kleen waste oil technician. “You don’t want a hundred-year-old sewer backing up ’cause Luigi’s Trattoria dumped bacon grease down da drain. Trust me.” She’s right to be emphatic – New York’s sewers have been plagued by massive “fatbergs” formed when grease hardens underground, causing clogs and floods. Studies found that grease causes a stunning 71% of sewer backups in NYC, a public nightmare that led to crackdowns on offenders.

New York City’s grease trap rules have deep roots. As early as the 19th century, cities recognized the need to stop grease from clogging drains – St. Paul, Minnesota required grease traps in restaurants back in 1883. New York eventually followed suit, and by the mid-20th century grease trap cleaning NYC was a routine part of running a kitchen. Today, the NYC Department of Environmental Protection (DEP) makes it clear: if you cook with oil, you must have a grease interceptor and keep it clean. The DEP sends inspectors to verify traps are installed and maintained, and only licensed plumbers can install these systems. Fail to clean your trap, and you risk foul odors, fines, or worse – in rare cases, neglected grease traps have even been known to catch fire or overflow disastrously.

For restaurants in older parts of town – think Lower Manhattan, where some buildings predate indoor plumbing – grease traps can be a challenge. In these dense urban blocks, many traps sit in cramped basements or sidewalk vaults. Grease trap cleaning Manhattan NY crews often work overnight, hauling pumper hoses through alleys to suction out rancid fat. It’s unglamorous, gritty work. “Ain’t no smell in the world like a week-old grease trap in July, I’ll tell ya that much,” laughs Tony, a Filta Kleen grease trap specialist, as he services a trap in a steamy Chinatown kitchen. He gestures to the glistening brown sludge being pumped into his truck. “Dis here is the real underbelly of the restaurant biz, pal. But you keep dis clean, you keep the city happy and your pipes flowin’. Everybody wins.” Fictional or not, Tony’s colorful insight speaks to an important truth: grease trap cleaning in NYC is vital to public infrastructure. It prevents sewer clogs and the horrific prospect of raw sewage (mixed with greasy runoff) backing up into eateries or city streets. Little wonder that high-volume establishments are legally required to service their traps quarterly, and even smaller operations at least twice a year.

By the 21st century, New York’s focus on kitchen emissions extended from below ground to the rooftop. Traditional hoods with fans did a decent job expelling smoke, but they didn’t address air quality for neighbors or the city at large. As the city grew more environmentally conscious, officials turned their eyes to the smoke itself – those wispy plumes of charbroiled burger grease and grilled steak drippings wafting from restaurant vents. Research by the NYC Health Department in the mid-2010s revealed something startling: approximately 1,400 tons of fine particulate matter (PM2.5) were spewing into the city’s air each year from commercial char-broilers, contributing to hundreds of premature deaths annually. In response, the City Council passed Local Law 38 of 2015, a landmark regulation targeting kitchen emissions. This law, which added Section 24-149.4 to the city’s administrative code, mandated that emission control devices – effectively pollution filters – be installed on commercial charbroilers that cook more than 875 pounds of meat per week. For the first time, even the invisible aspects of kitchen exhaust were being strictly regulated.

What did these emission control devices mean in practice? In most cases, it meant electrostatic precipitators – advanced filtration units that use an electrical charge to trap smoke and grease particles. These precipitators for restaurants act like high-tech air scrubbers: as greasy fumes pass through, metal plates zapped with electricity capture and collect the particles, allowing much cleaner air to exit the exhaust. A DEP rule enacted in 2016 fleshed out the details, requiring that whatever device is used must cut particulate emissions by at least 75%. In essence, New York’s busiest barbecue joints, steakhouses, and burger spots now needed to install precipitator kitchen systems or similar filters or face penalties. Existing restaurants were given a grace period – many had up to five years to retrofit their vents with compliant gear. By 2020, the city had fully phased in the requirement: any high-volume kitchen that hadn’t yet added a precipitator was officially on notice.

An electrostatic precipitator unit on a New York City restaurant rooftop filters grease and smoke from the kitchen exhaust. NYC’s Local Law 38/2015 requires such devices on heavy-use charbroilers to cut air pollution, giving existing kitchens until 2020–2025 to comply. All emission control systems must be regularly cleaned and serviced by technicians with FDNY certification (Certificate of Fitness P-64) to ensure they remain effective.

For companies like Filta Kleen, which had started out decades ago cleaning hoods and ducts, this was a new chapter. Suddenly “hood guys” also had to be precipitator installers and technicians. Installing the hefty metal boxes on rooftops or in back alleys was one thing; keeping them running was another. Much like grease traps, if you don’t clean a precipitator, it can clog up – only instead of clogging a sewer, it could choke off a restaurant’s ventilation or become a fire hazard itself. The FDNY instituted a special Certificate of Fitness (P-64) for commercial kitchen exhaust and precipitator cleaning technicians, ensuring that those maintaining these units know their stuff. “We’re basically electricians, plumbers, and chimney sweeps all in one now,” jokes Miguel, a Filta Kleen precipitator specialist, tightening down the access panel on a unit atop a Manhattan steakhouse. With a view of the Empire State Building behind him, he reflects on the changes: “The city’s changed the rules on us a few times. Sure it’s more work to keep these machines clean, but hey, the air smells a lot better than it used to. You ask me, dat’s progress.”

Running a commercial kitchen in NYC has never been a “set it and forget it” operation – and the evolution of hood and grease systems underscores why. Each advancement, from basic vent hoods to modern electrostatic precipitators, has come with new responsibilities and challenges for restaurateurs and the service companies that support them. Hood exhaust repair crews are on call 24/7, because a broken exhaust fan in a Manhattan restaurant can halt business instantly (city health inspectors will shut down a kitchen that isn’t ventilating properly). Grease trap cleaning teams likewise operate on tight schedules; they often have to slip into that brief window after the dinner rush and before the breakfast crowd to pump out the traps in thousands of NYC eateries. It’s costly, strenuous, often thankless work – but it keeps the city’s food scene running safely.

Filta Kleen, for instance, has been in the business for over 60 years, and in that time they’ve seen technologies and regulations come and go. Yet, the core challenge remains the same: keep the grease under control. Whether it’s scraping inches of char off a diner’s flue or fine-tuning a digital controller on a state-of-the-art precipitator, the goal is a cleaner, safer kitchen. And the regulatory history shows an unmistakable trend – ever tighter standards. “Look, New York ain’t gonna loosen regs any time soon,” says a Filta Kleen manager with a shrug. “If anything, they’re gonna get tougher. And honestly? Good. It keeps everyone on their toes, us included.” This pragmatic attitude is common among the city’s exhaust pros, who take a certain pride in meeting NYC’s high bar. The image of the gruff, streetwise hood cleaner belies a deep professionalism: these are tradespeople who must understand fire code, environmental law, mechanical engineering, and even a bit of chemistry (to handle the caustic degreasers and the science of smoke capture).

From the coal-fired chophouses of a century ago to today’s hip fusion restaurants with open kitchens, the evolution of New York’s commercial kitchen ventilation tells a story of learning from adversity. Every devastating restaurant fire taught lessons that led to better hood designs or stricter cleaning regimens. Every flooded basement or clogged sewer from grease prompted the city to tighten its grip on waste handling. The result is a metropolis where grease trap cleaning Manhattan NY services and high-tech hood installation firms are as essential to the food ecosystem as chefs and waiters.

In true New York fashion, even this behind-the-scenes industry has its colorful characters and stories. The Filta Kleen crews swapping tales at an all-night diner counter after a long shift represent the human side of all these regulations and technologies. They’ll joke about “the one time the rat came outta the grease trap” or the legendary tale of a 40-year-old exhaust duct that finally got replaced. Through their joking, there’s an undercurrent of pride: they know they’re keeping New Yorkers safe, one greasy job at a time. “End of the day, you do the work ’cause somebody’s gotta do it, and we do it right,” says Joey Two-Tools, finishing his coffee as dawn breaks over the city. Hood exhaust repair, grease trap cleaning, precipitators for restaurants – it’s not the stuff of celebrity chef shows, but it’s the backbone of every kitchen in town. And in a city that never sleeps (and never stops eating), that backbone better be strong.

As New York City moves forward, the marriage of legislation, technology, and elbow grease will continue to shape its culinary landscape. Diners may never see the grease traps in the basement or the precipitator on the roof, but they can breathe easier (literally) and enjoy their meals safely thanks to the hood installers and cleaning crews who toil in the shadows. In the end, it’s a uniquely New York tale: tough jobs, strict rules, loud personalities, and an undeniable Innovation.

Gabriel Jean

Filta Kleen

+1 718-495-4747

email us here

Visit us on social media:

LinkedIn

Instagram

Facebook

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.